배관 진동에 대한 정성적 평가 기준

Qualitative Assessment for Pipe vibration

설계 단계에서 New plant, Existing plant의 배관 시스템에 대한 잠재적인 진동 가진원을 평가하고, 정량적 평가(Likelihood of failure, LOF)에 대한 기초자료로 활용하기 위한 정량적 평가(Qualitative Assessment) 업무가 진행됩니다. Qualitative Assessment 평가 단계에서는 아래와 같은 배관 진동원의 가능성 유무를 판별합니다.

- Flow induced turbulence

- Flowinduced pulsation

- High frequency acoustic excitation

- Mechanical excitation

- Pulsation from reciprocating compressor or pump

- Pulsation from rotating stall

- Cavitation and flashing

- Surge and momentum changes

- Vortes shedding from intrusive elements

[ Guideline for Qualitative Assessment for Piping System ]

| Item | Aspect | Applicable process fluid(s) |

Likelihood Classification | Potential excitation mechanism(s) |

||

| Low | Medium | High | ||||

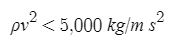

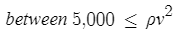

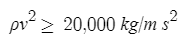

| 1 | What is the maximum value of kinetic energy(pv2) of the process fluid within the system under consideration? | All | Flow induced turbulence(All fluids) refer to Scetion T2.2 Flow induced pulsation(Gases only) refer to Scetion T2.6 |

|||

| 2 | Is choked flow possible or are sonic flow velocities likely to be encountered? | Gas | No | Yes | High frequency acoustic excitation refer to Section T2.7 | |

| 3 | Is there any rotating or reciprocating machinery? | All | No | rotating equipment only |

reciprocating equipment |

Mechanical excitation refer to Section T2.3 |

| 4 | Are there any positive displacement pumps or compressors? | All | No | Screw/gear type positive displacement machine |

reciprocating type positive displacement machine |

Pulsation - reciprocating refer to Section T2.4 |

| 5 | Are there any centrifugal compressors which have the potential to operate under rotating stall conditions? | Gas | No | Compressor has stall charateristics but operational restraints in place to ensure that rotating stall is not encountered | Stall rotating condition unknown. Compressor has rotating stall charateristics and may operate at conditions that will give rise to stall conditions |

Pulsation - rotating stall refer to Section T2.5 |

| 6 | Are there any systems which may exhibit flashing or cavitation? | Liquid / Multiphase |

No | Yes | Cavitation and Flashing refer to Section T2.9 | |

| 7 | Are there any systems with fast acting opening or closing valves? | All | No | Yes | Surge/Momentum changes refer to Section T2.8 |

|

| 8 | Are there intrusive elements in the process stream? | Gas / Liquid |

No | Yes | Vortex shedding from intrusive elements to refer to TM-04 | |

| 9 | Is there a possibility of slug flow? | Multiphase | No | Yes | Slug flow - seek specialist advice | |

| 10 | Is there a history of pipework vibration issues, or are there any systems which are similar to those on another plant which have a known history of pipework vibration issues? | All | No | Yes: however, suitable corrective action in place and validated for the complete operating envelope. | Yes | Known vibration refer to Chapter4 |

(참고: Energy Instiude, Guidelines for the avoidance of vibration induced fatigue failure in process pipework, Jan. 2008)

배관 진동에 관한 문의는 02-707-1545,

admin@inertance.com으로 부탁드립니다.

주식회사 이너턴스

'플랜트 기계배관 진동 기준' 카테고리의 다른 글

| Flow Induced Vibration (FIV) 평가 기준 (0) | 2022.02.11 |

|---|---|

| Design Criteria for Torsional Virbation, Reciprocating Pump (0) | 2021.12.13 |

| Acoustic Induced Vibration (AIV) 평가 기준 (0) | 2021.10.07 |

| EI Guidelines for AIV (0) | 2020.09.17 |

| Cyclic Allowable Stress Criteria (0) | 2020.09.02 |

댓글